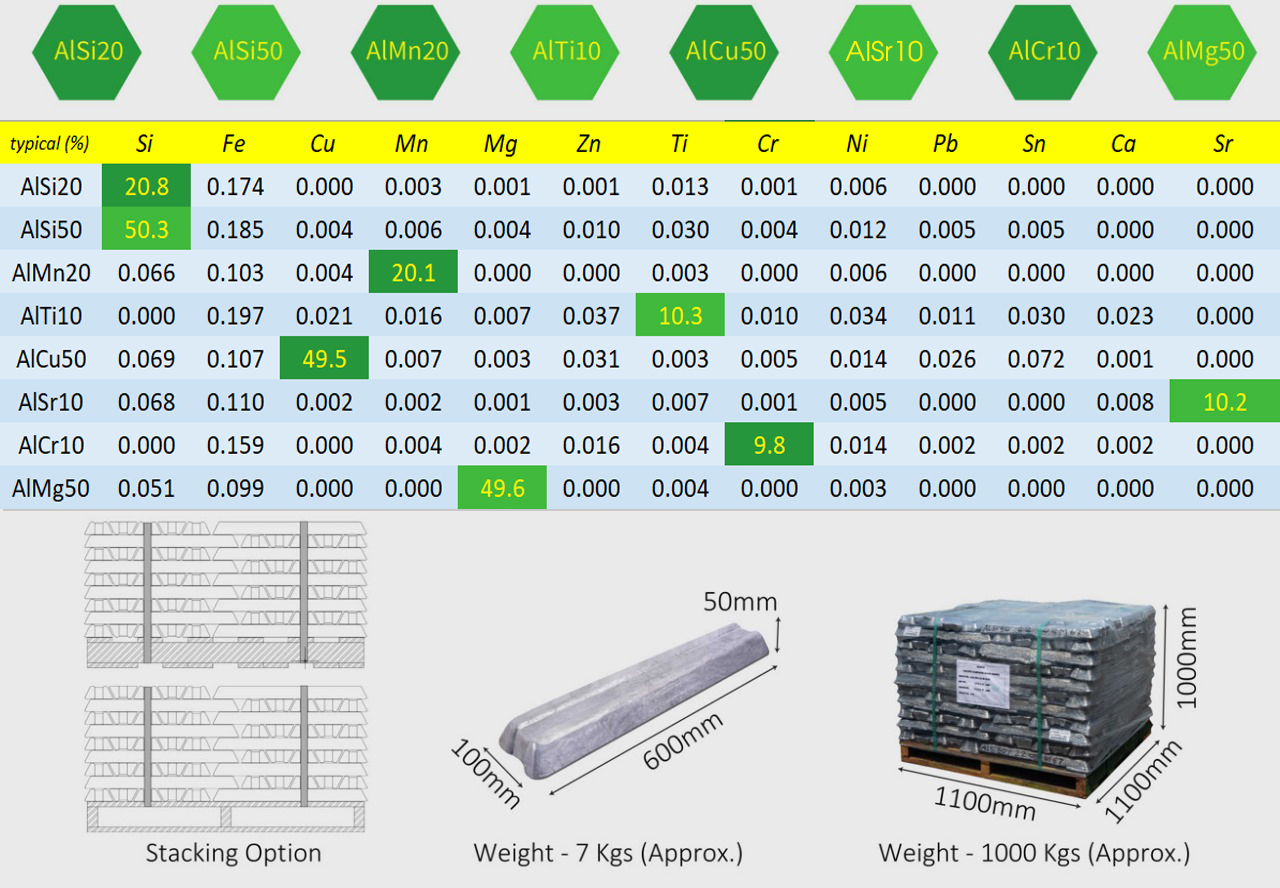

Master Alloys

BAMCO's induction technology ensures best homogeneity.

BAMCO's aluminum master alloys are ideal for precise melt compositions in billets, slabs, and wires, covering elements like silicon, copper, manganese, and more. Known for high yield, fast dissolution, and minimal unwanted inclusions, these alloys make alloying easier.

BAMCO's master alloys are produced in induction furnaces capable of temperatures exceeding 1200°C, ensuring complete dissolution of additives such as silicon and titanium into the aluminium.

Once the ingredients are melted, the oxides separate and are removed from the melt surface. The use of primary aluminium from a local smelter results in minimal inclusion of unwanted elements. Both factors contribute to BAMCO's master alloys being of high purity.

Pouring is carried out with inductive stirring to ensure homogeneity of the alloy. The metal is thoroughly analyzed before, during, and after casting to ensure it meets precise standards.

HOW WE PRODUCE MASTER ALLOYS

Inductive melting of primary aluminium

Alloying at high temperature

Inductive stirring

High temperature ingot casting