Foundry Alloys

Liquid primary aluminium feeds production for highest efficiency and purity

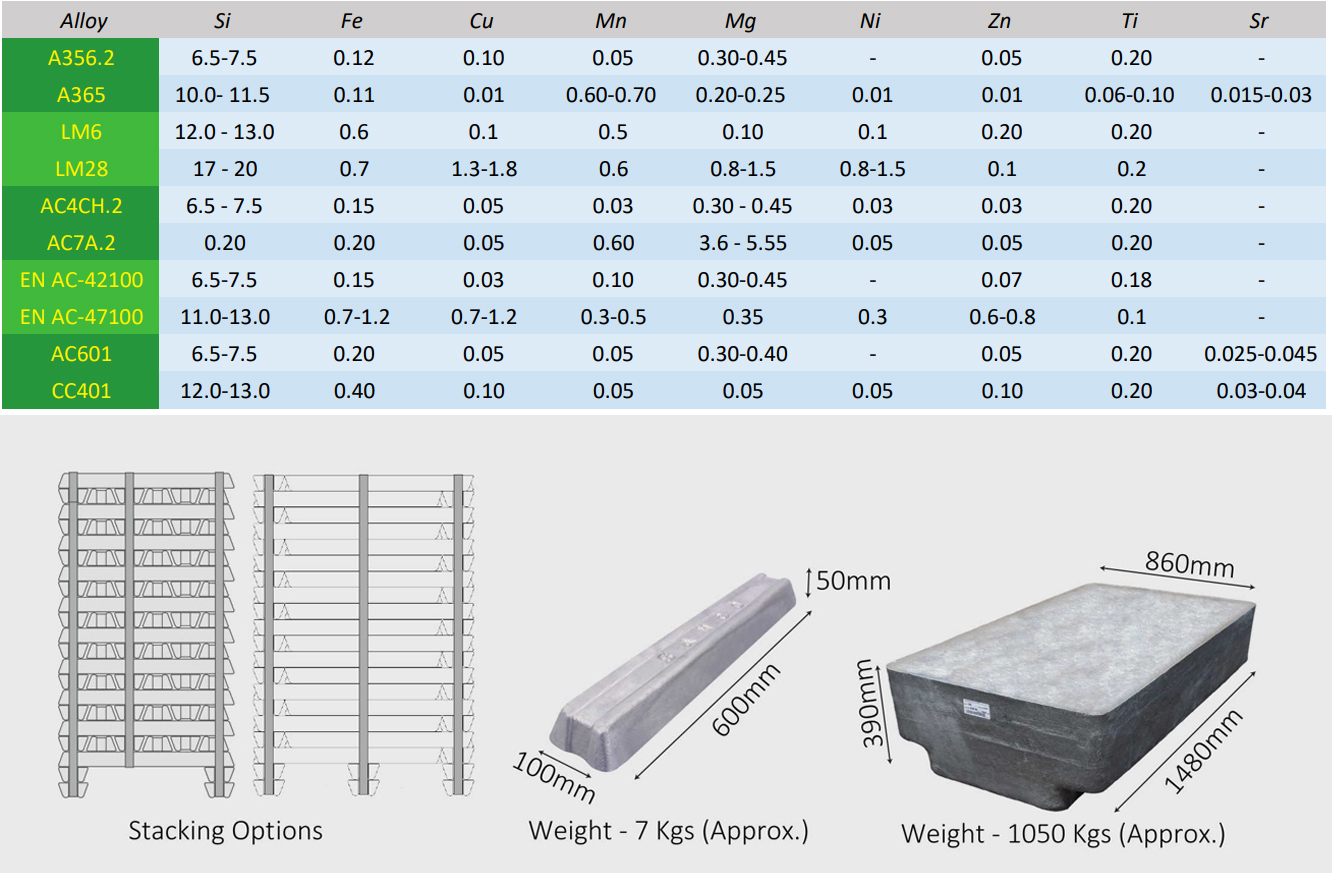

BAMCO produces foundry alloys according to all current standards as well as custom made in the form of ingots and sows. The foundry industry appreciates the high purity of the alloys for castings for extreme conditions. BAMCO offers its customers an extremely flexible service to ideally adapt to the requirements of the market.

Foundry Alloys

Foundry Alloys are produced from primary aluminum, supplied in liquid form from a local smelter. BAMCO operates two 12-ton capacity furnaces where aluminum is alloyed to meet customer specifications.

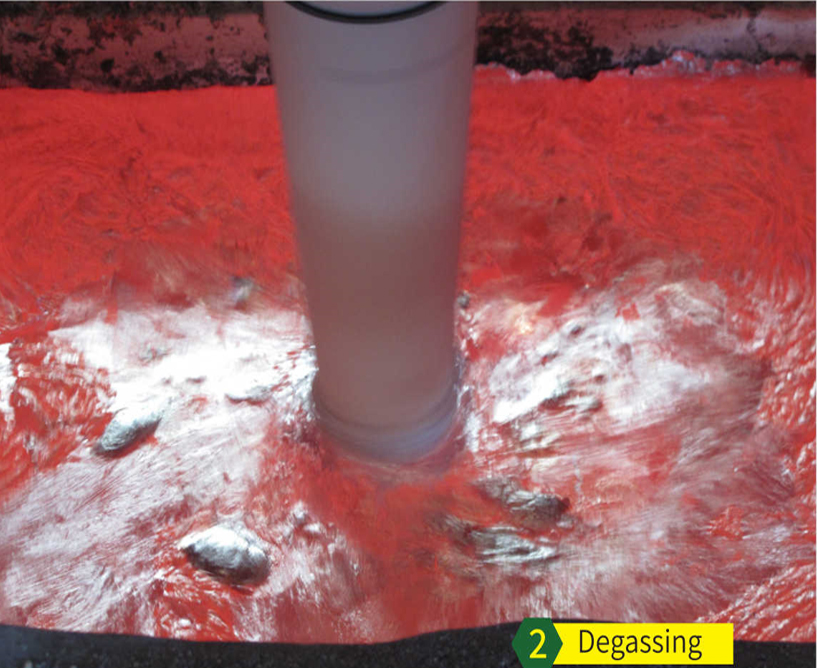

The metal is degassed using an in-line launder treatment process and thoroughly analyzed before, during, and after casting. Final cast products include 7 kg ingots and sows in varying weights.

Applications

BAMCO’s Aluminium Foundry Alloys are used across various casting industries, such as:

- Die casting

- Low pressure die casting

- Sand casting

Key Applications

These alloys are widely used in the automotive industry for:

- Wheels and engine components such as cylinder heads and pistons

- Electrical connectors

- General die castings such as pump housings

- Corrosion-resistant coatings on steel sheets

- Plain bearings

HOW WE PRODUCE FOUNDRY ALLOYS

Intake of liquid primary aluminium

Alloying of silicon, magnesium, copper

Degassing

Casting to ingots